Wires & Cables

Building Wires

Energy efficient wires range 0.75sq.mm to 16 sq.mm with different Insulation properties.

Single Core Industrial Flexibles

Energy Efficient Wires Range 0.50sq.mm to 1000 sq.mm in Class 5 copper conductors with different insulation properties.

Handling, Storage and Laying of Cables

Cable Inspection

Inspect every cable reel for damage before accepting the shipment. Be particularly alert for cable damage if;

- A reel is lying flat on its side

- Several reels are stacked

- Nails have been driven into reel flanges to secure shipping blocks

- A reel flange is damaged

- A cable covering is removed, stained or damaged

- A cable end seal is removed or damaged. A reel has been dropped (hidden damage likely)

Cable Handling & Storage

Damage to cables can occur due to the incorrect handling to which the drums and cables may be subjected; causing breakdown of the drum flanges and in exceptional cases, movement of the drum barrel takes place. Once this breakdown of the drum occurs, the cable is immediately exposed to damage. Cables damaged during handling & storage can cause service failures when the subject cable is put to use.

Thus the following is a list of Do's & Don'ts that should be followed while handling and storing the cables before it is put to use.

| Do's | Don'ts | ||

|---|---|---|---|

|

When off loading reels from a truck, lower reels carefully using a hydraulic gate, hoist or forklift truck. |  |

Never drop reels. If reels must be rolled, roll in opposite direction of the cable wraps to keep cable from loosening on the reel. |

|

If a fork lift is used, approach the feel from the flange side. Position the forks such that the reel is lifted by both reel flanges. Also Consideration should be given to, Traffic patterns during off – loading & damage during the time in storage. |  |

Do not allow the lift forks to contact the cable. Care must be taken by the fork lift operator not to make sudden turns or stops. |

|

Cables reels should be stored on hard surfaces resting on the flanges edge (flanges vertical). Align reels flange to flange and, if possible arrange so that first in is first out. |  |

Multiple reels stacked on top of each other("Pancake" storage) is not recommended for cable drums. The weight of the stack can total thousands of kgs. Creating an enormous load on the bottom reel. Also, damage to the reel and/or cable will likely occur when the reel is flipped for transit. A concentration of stress on the reel flange may cause it to break and subsequently damage the cable. |

|

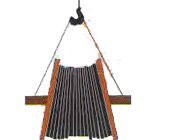

When using a hoist, install a mandrel through the reel arbor holes and attach a sling. Use a spreader bar approximately 6 inches longer than the overall reel width placed between the sling ends just above the reel flanges. |  |

This may lead to the bending of the reel flanges and mashing the cable. |

Pre- Installation

To ensure the safety during cable installation, following shall be checked prior to installation.

- The cable is selected is proper for designed application.

- The cable has not been damaged in transit or storage.

Review all applicable state and national codes to verify that the cable chosen is appropriate for the job. Also consult your local electricity authority. Next, you must identify any existing cable damage and prevent any further damaged from occurring. This is done through proper cable inspection, handling and storage.

Installation & Laying

Mechanical stresses during installation are generally more severe than those encountered while in service. Thus care should be taken as regards to the following while installation and laying of cables:

- Polycab recommend the lying and installation of cables as per IS: 1255 / 84.

- Care shall be taken during laying to avoid sharp bending, and twisting.

- Cable shall be unwound from the drum by lifting the drum on the center.

- Shaft supported both ends with suitable jacks / stands.

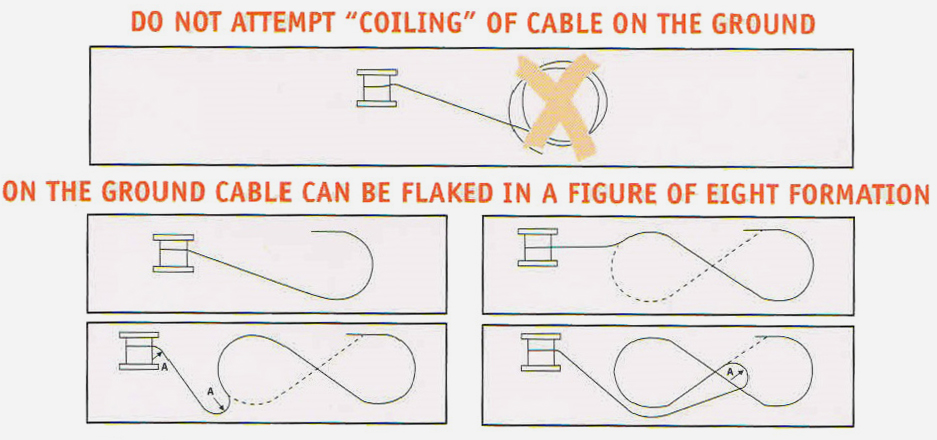

- Under no circumstances the cable winding shall be lifted off a coil or drum laying flat at the flanges. This would cause serious twist and damages.

- Suitable protection shall be provided to the cables against mechanical damages, it includes covers, pipes, etc.

Recommended Minimum Bending Radius for Heavy Duty Cables.

- Single Core: 20 x D

- Multi Core: 15 x D

- Where D = diameter of cable in mm

Recommended Safe Pulling Force with Stockings:

- For Unarmoured Cable: P = 5 D2

- For Armoured Cable: P = 9 D2

Where P = Pulling Force

Where D = Diameter of Cable in mm

Recommended Safe Pulling Force when Pulled with Pulling Eye:

- For Aluminum Conductor: 30 N / mm2

- For Copper Conductor: 50 N / mm2